Germany-HAIMER

Where are you now:HOME > PRODUCTS > Mechanical Equipment > Germany-HAIMER

- Product name:TD Automatic

- Subordinate category:Mechanical Equipment

- Owned brand:Germany-HAIMER

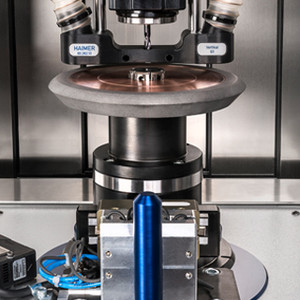

Tool Dynamic TD Automatic

Automatic Balancing Machine

Main features •Automatic measuring and compensation of unbalance on 1 and 2 planes •Automatic correction of the unbalance by drilling or milling •Comfortable handling via touchscreen •Balancing software TDC 4.0 |

We take balancing to the next level: faster, better, more efficient!

The Tool Dynamic TD Automatic is a truly universal CNC-based balancing machine with automated correction of the unbalance. It automatically compensates the unbalance in one or two planes by drilling or milling. The machine can work vertically and horizontally. The balancing machine is controlled by an integrated 19’’ touchscreen. The numerical control is a Siemens 840DSL, which can be accessed simultaneously with the balancing software.

Automatic Balancing – that’s how it works:

After measuring the unbalance the software calculates how deep the machine must drill, mill or grind in order to compensate the unbalance. The balancing spindle turns into the correct position. The integrated CNC unit moves to the pre-selected balancing plane and automatically removes the appropriate amount of material. Done. Balancing could not be any quicker or easier. Errors, such as those caused by incorrect marking on the tool holder or through inadvertently incorrect drilling depths are no longer an issue.

•Measures and compensates unbalance in one step

•Rapid, easy and economic

•No incorrect drilling on the rotor

•Integration into automatic production lines is possible

•Specific software for particular methods of balancing available

Tool Dynamic TD Automatic – automatic vertical CNC based balancing machine: Maximum of comfort, maximum of process reliability with highest efficiency and precision.

Your benefits at a glance:

•Correction of unbalance is fully automated by drilling, milling or grinding in one or two planes with the help of an integrated simultaneous 4 Axis CNC machine tool

•Integrated and exchangeable balancing adapters clamp rotors with highest precision. There are standard adapters for all common interfaces and customized solutions for special purposes

•Gripper for automated indexing (optional). It can be mounted without any additional tools and changed together with the balancing adapter

•Chips are removed by exhaust (suction) equipment

•Central lubrication enables a nearly maintenance free 3 shift use

•Balancing spindle and control box are cooled

•Dynamic measuring mode enables shortest measuring times – balance and control your rotors in record time!

•Simple measuring mode: Measuring, drilling and checking in less than 1 minute!

•Integration of robot unit is possible – embody your balancing machine in your production line!

•Intelligent software allows the fast and efficient re-balancing of already balanced rotors

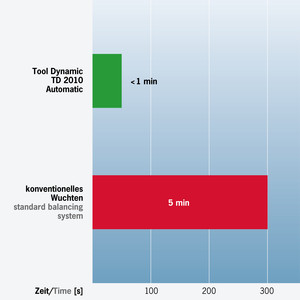

Balancing in record time! •Balancing: Simple measuring mode, drilling and checking •TD Automatic: Balancing in less than 60 s •Conventional balancing: Balancing in less than 300 s |

Automation concept with KUKA flexFELLOW •Automatic and flexible assembly with mobile robot unit KUKA flexFELLOW possible •Touch-sensitive features make it possible to permanently eliminate bulky safety guards •Reduced space requirements for automation |

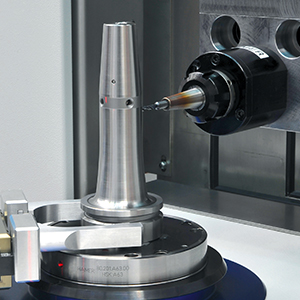

Automatic balancing •Automated compensation of unbalance via CNC machining unit |

Automatic balancing •Integrated balancing adapter and gripper for automatic index measuring |

Integrated control and balancing software •Numerical control Siemens 840 Dsl •Balancing software Tool Dynamic TDC 4.0 |

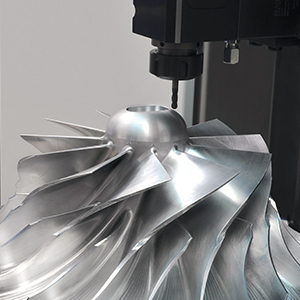

Application example: Compressor wheel for turbocharger •Balancing by peripheral milling axial |

Application example: Balancing of grinding wheels by axial drilling •Balanced grinding wheels reduce the surface roughness of the work piece what leads to a remarkable increase of the process performance and to a higher precision of the end product. |

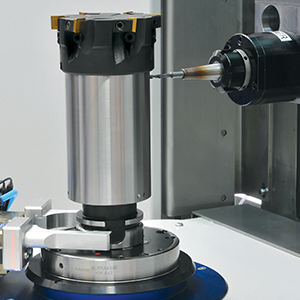

Application example: Balancing of a milling head in 2 planes •Long projecting tools must be balanced in two planes in order to eliminate the couple unbalance (dynamic balancing). At longer tools that leads to a higher cutting capacity and a better surface finish. |

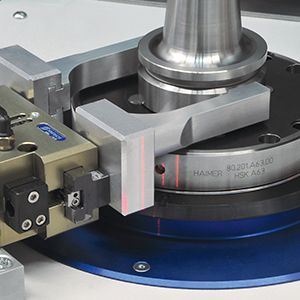

HAIMER balancing adapter with automatic clamping •μm precise clamping for highest measuring accuracy and repeatability •Easy and quickest changing due to compact design. A re-calibration of the machine is not neccessary |

| Technical data | |

| Measuring accuracy [gmm] | < 0,5 |

| Max. tool diameter [mm] | 400 |

| Max. tool length [mm] | 600 |

| Max. tool weight [kg] | 50 |

| Operational range X-axis [mm] | 160 |

| Operational range Y-axis [mm] | 400 |

| Operational range Z-axis [mm] | 250 |

| Operational range B-axis [mm] | 360° |

| Rapid mode on all axis [m/min] | 20 |

| Max. rpm balancing spindle [U/min] | 1400 |

| Max. torque balancing spindle [Nm] | 35 |

| Interface CNC unit | VDI 30 |

| Max. rpm CNC unit [U/min] (Adjustable) | 6000 |

| Max. torque CNC unit [Nm] (At S3-25%) | 15 |

| Max. drilling capacity (In hardened steel HRC 60) | Ø 10 mm |

| Operational range of rotor in horizontal mode Max. diameter [mm] | 400 |

| Operational range of rotor in horizontal mode Max. height [mm] | 250 |

| Operational range of rotor in vertical mode Max. diameter [mm] | 400 |

| Operational range of rotor in vertical mode Max. height [mm] | 280 |