Germany-HAIMER

Where are you now:HOME > PRODUCTS > Mechanical Equipment > Germany-HAIMER

- Product name:TD Preset

- Subordinate category:Mechanical Equipment

- Owned brand:Germany-HAIMER

Tool Dynamic TD Preset

Tool Balancing and Presetting

Main features •Measuring and compensation of unbalance on 1 and 2 planes •Correction of the unbalance by radial drilling or balancing rings •Comfortable handling via touchscreen •Base made polymer concrete for highest measuring accuracy |

Two approved systems – a trendsetting innovation.

Tool balancing and presetting are key elements of modern manufacturing. It is obviously a good idea to combine these two procedures. The Tool Dynamic TD Preset is a perfect combination of HAIMER’s balancing and Zoller’s measuring technology. The tool is clamped in the high precision balancing spindle fitted with HAIMER’s proven adapter system. This saves time and increases accuracy because the tool does not have to be re-clamped.

•Forward-looking state-of-the-art technology by technology leaders

•Highest efficiency and saved time by combining two production stages

•Utmost precision due to high precision clamping in HAIMER’s balancing adapters

•Reasonable price and efficiency ratio

•Needs little space

•Simple and logical operation

•Adapter for all interfaces

•Highest possible measuring comfort

Picture shows Tool Dynamic Preset with Control Terminal.

Tool presetting •Measuring technology pilot 3.0 with high resolution camera and digital photo processing. |

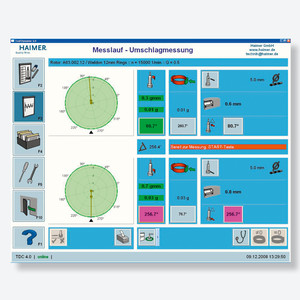

Software for professionals •The balancing software TDC 4.0 in combination with the photo processing software pilot 3.0 provides various options for measuring and balancing clearly arranged in menus. |

Tool Dynamic control terminal •High quality touchscreen with hardened glass surface for easiest control •Traditional input with keyboard and mouse possible •Drawer for balancing adapter and tools •Storing facility for printers |

Tool Dynamic Software TDC 4.0 •New intellignet balancing software •User interface completely made up of graphics •Intuitive user guidance •Graphical help and assistant functions guides through all function processes |

HAIMER balancing adapter with automatic clamping •μm precise clamping for highest measuring accuracy and repeatability •Easy and quickest changing due to compact design. A re-calibration of the machine is not neccessary |

| Equipment | |

Base made of polymer concrete Base made of polymer concrete | Highest measuring accuracy due to heavy base |

User interface User interface | Integrated user interface for easy handling of the machine |

Optical indexing help Optical indexing help | Indication of the exact spindle angle position on display |

Laser marking Laser marking | Indicates the position of unbalance and correction with a laser |

Print label Print label | Print balancing result on label |

Drilling radial Drilling radial | Balancing by drilling radially |

Software for compensation with balancing rings Software for compensation with balancing rings | Balancing by rings or other movable weights |

Index balancing Index balancing | Compensation of measuring errors by index balancing (2 measuring runs, indexing angle 180°) |

Balancing with spindle compensation Balancing with spindle compensation | Quick and precise measuring of repetition parts (single measuring run) |

Balancing in 1 plane Balancing in 1 plane | Measuring and compensation of unbalance in 1 plane (static) |

Balancing in 2 planes Balancing in 2 planes | Measuring and compensation of unbalance in 2 planes (dynamic unbalance) |

Rack for accessories Rack for accessories | Storage rack with two integrated drawers for balancing adapters and further accessories |

Balancing software TDC 4.0 Balancing software TDC 4.0 | New software with user-friendly graphical interface and touchscreen-control |

Automatic indexing Automatic indexing | Turn the spindle on the selected angle position and simplifies exact positioning of spindle Tool Dynamic - Rack for accessories |

Control Terminal incl. Touchscreen for TD Preset Control Terminal incl. Touchscreen for TD Preset | Console for storage of touchscreen, keyboard, mouse, printer, and further accessories (only together with Balancing software TDC 4.0) |

Touchscreen Touchscreen | TFT monitor with touchscreen |

2nd Laser (from top) 2nd Laser (from top) | Second laser for laser marking from top |

Deutsch/English/Français/Italiano/Español Deutsch/English/Français/Italiano/Español | Languages for user interface for internal display |

| Technical data | |

| Dimensions [mm]1600 x 1800 x 820 | 1600 x 1800 x 820 |

| Weight [kg] | 450 |

| Spindle speed [rpm] | 300 - 1100 |

| Measuring accuracy [gmm] | < 0,5 |

| Power requirements [V/Hz] | 230 / 50 - 60 |

| Power usage [kW] | 0.4 |

| Compressed air [bar] | 6 |

| Air comsumption [l/h] | 30 |

| Max. tool length (balancing) [mm] | 700 |

| Max. tool length (presetting) [mm] | 450 |

| Max. tool diameter [mm] | 400 |

| Max. tool weight [kg] | 30 |